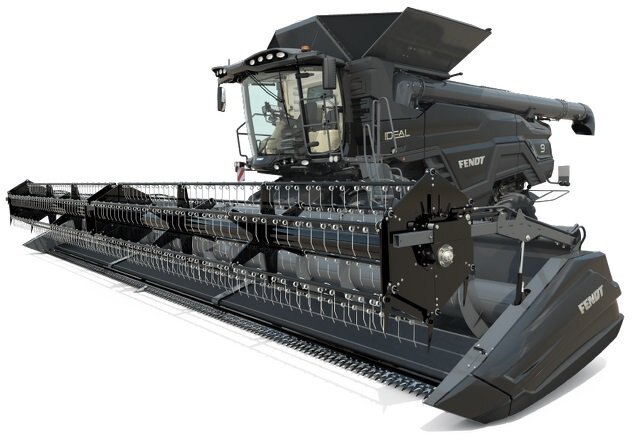

Fendt IDEAL

Make your Harvest Legendary with the Fendt IDEAL CombineTime for something completely different Fendt IDEAL. A combine harvester that works wonders in the shortest harvest windows with uncompromising quality and unconditional reliability. A smart solution that lets you experience your harvest like never before, with the latest sensors and smart networking. | ||||||||||||

Redefine your harvest with our combine.The Fendt IDEAL was developed in the global AGCO Centers of Excellence for harvesting technology. Countless farmers and contractors from around the world were asked what combine requirements would make their IDEAL harvest. It's the culmination of this customer input, the combined experience of our developers and the chance to test the Fendt IDEAL all year round in different regions under the harshest operating conditions, that make the Fendt IDEAL the most modern and innovative combine on the market. | ||||||||||||

| ||||||||||||

| ||||||||||||

More power. More output. More comfort.It's time for new dimensions. Exceptional conditions require exceptional performance – both from us and our machines. A clear view of the cutter unit and in-feed with easy ergonomic steering. IDEALdrive brings ergonomics and efficiency to your working day. |

|

|

|

|

|

|

|

|

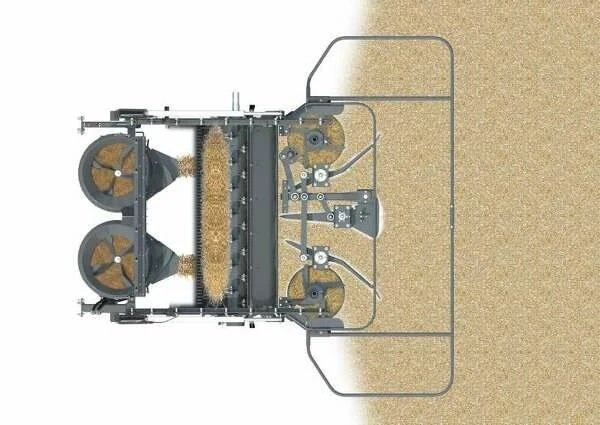

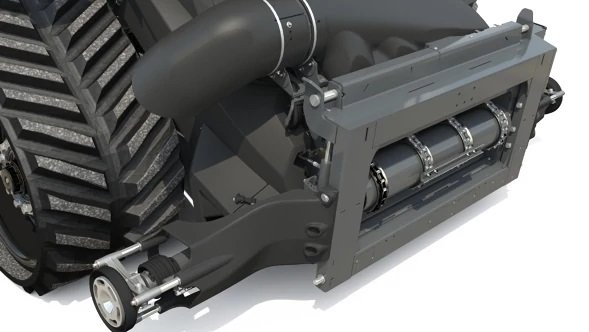

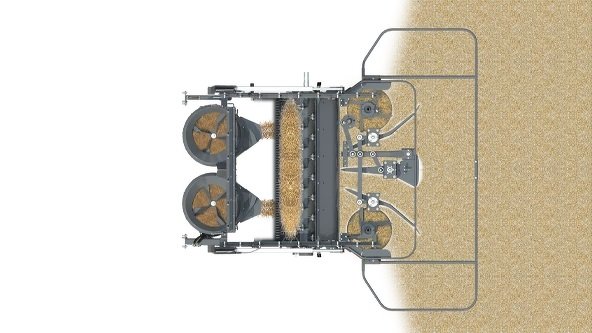

Strong right from the start - to get the best results, everything has to be right from the start. That's why all Fendt IDEAL combines work with the latest generation of the world's most esteemed PowerFlow headers. |

|

|

|

|

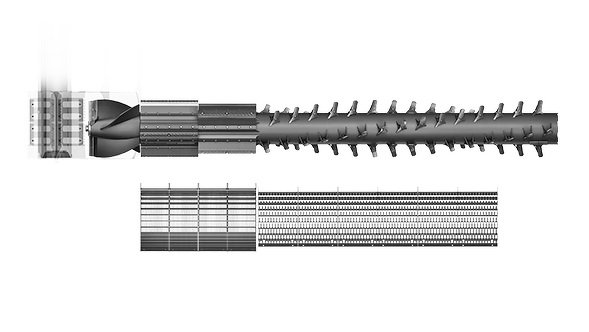

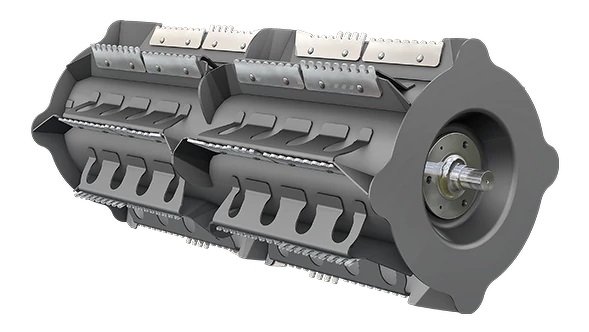

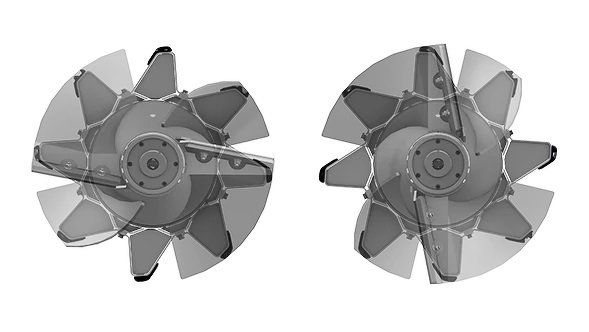

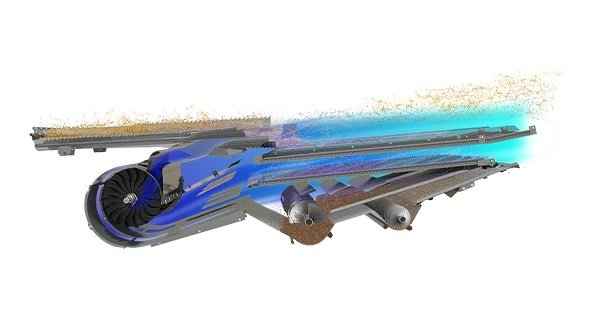

What makes the Fendt IDEAL stand out from other combines is the excellent Single or Dual Helix processor. The concept of the Helix processor unites the market requirements such as maximum output, best grain quality and low energy consumption with optimum straw quality. |

|

|

|

|

|

|

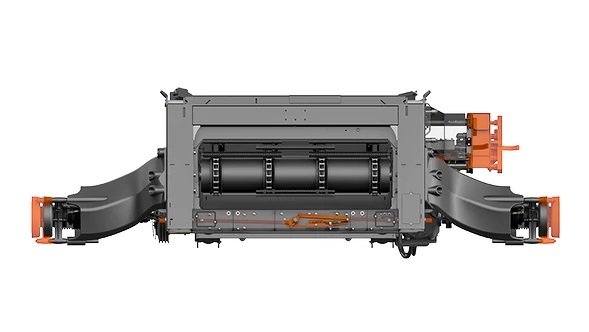

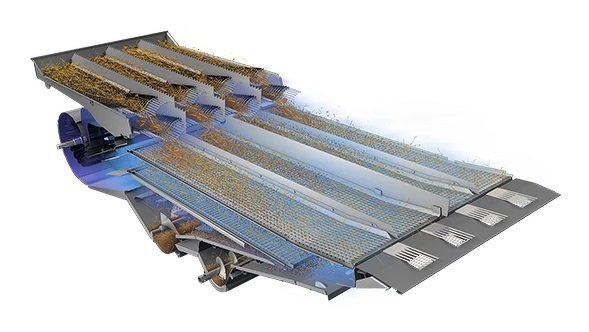

The cleaning and separation performance of the IDEAL is outstanding. Fendt IDEAL models are equipped with the unique and ingeniously simple IDEALbalance™ system and a long sieeve box to ensure that only clean crop reaches the grain tank. |

|

|

|

|

|

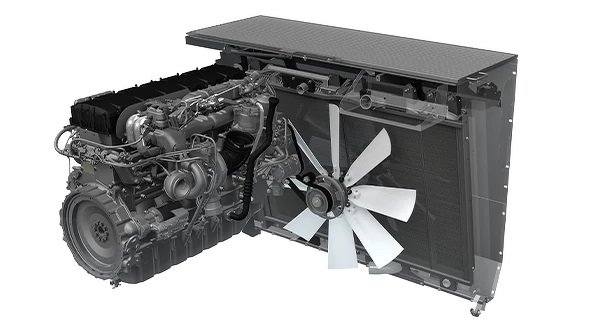

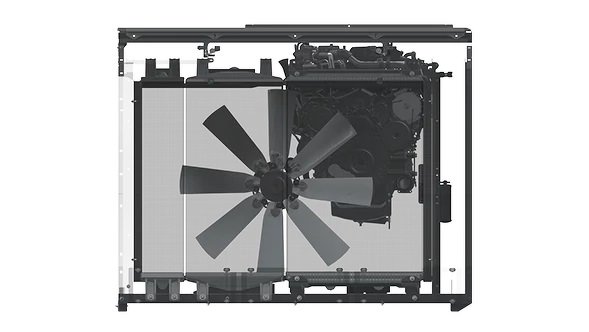

Getting ahead and doing more has never been easier. With efficient and reliable AGCO Power and MAN engines and proven transmission technology, the Fendt IDEAL is ready for any job. In addition to comfortable and efficient operation, reliability is an absolute strength. |

|

|

|

|

|

The IDEAL workplace for you. The Fendt IDEAL offers a comfortable cab with the best possible view of the cutterbar and all functions, making harvesting a breeze. |

|

|

|

|

| Name | Link |

| Product Brochure | Download |

Your IDEAL Story

Your IDEAL Story IDEALdrive - Everything at hand

IDEALdrive - Everything at hand IDEALharves

IDEALharves IDEALbalance™ Syste

IDEALbalance™ Syste ActiveSpread SwingFlo

ActiveSpread SwingFlo Grain tank and discharg

Grain tank and discharg Adjustable outlet spout on the unloader tub

Adjustable outlet spout on the unloader tub Fendt TI Headlan

Fendt TI Headlan Always in the right position

Always in the right position Fendt Autodock™ Crop elevator

Fendt Autodock™ Crop elevator Dust extraction on the crop elevator

Dust extraction on the crop elevator Superior rotors: Single Helix.

Superior rotors: Single Helix. Superior rotors: Dual Helix.

Superior rotors: Dual Helix. The Helix Processor: simply unique

The Helix Processor: simply unique RotorFeeder feeding drum

RotorFeeder feeding drum Gentle feed, low power requirement

Gentle feed, low power requirement Triple fan

Triple fan Separate post-threshing

Separate post-threshing Superior cleaning

Superior cleaning Choose between 3 straw distribution settings

Choose between 3 straw distribution settings Engines & reversible fan

Engines & reversible fan Revolutionary AirSense® Cooling

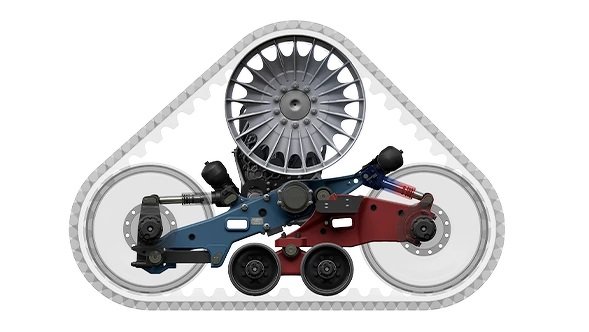

Revolutionary AirSense® Cooling Maximum propulsion

Maximum propulsion The Fendt IDEAL gearbox

The Fendt IDEAL gearbox Workplace with the best view

Workplace with the best view Everything under control

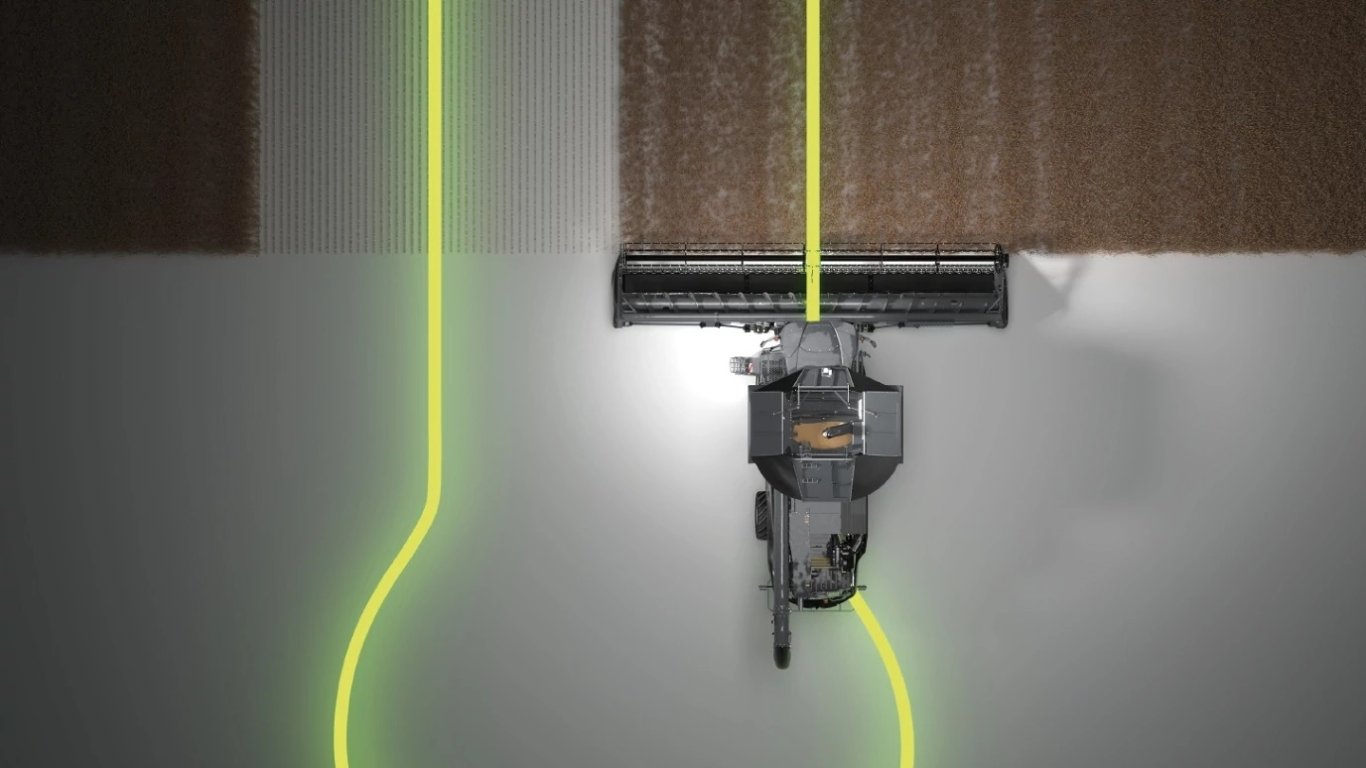

Everything under control Fendt VarioGuide

Fendt VarioGuide NovAtel and Trimble

NovAtel and Trimble