Fendt 314 PROFI+

|

Fendt 300 Vario

Always the right choice. For 40 years. And for many years to come. |

| The Fendt 300 has been a unique success story since 1980, with 140,000 vehicles sold. This series is perfect for most farms in terms of performance, quality, versatility and outstanding residual value. The 4th generation Vario features the all-new driver’s workstation with FendtONE as well as the high-end model 314 with 152 hp max. output. The concept seamlessly unites machine and office. With this, the 300 is again a pioneer among compact standard tractors. |

| Engine | 314 |

|

Maximum power to ECE R 120 |

104/142 |

|

|

|

High ground clearance for plant protection, even in late growth stages

Plant protection and fertilization in late growth stages increase yield. The 300 offers you the high ground clearance required for this. 500 mm for use with special crops. 500 mm = for the tire options: 270/95 R32 front and 270/95 R48 rear. |

|

|

|

|

|

|

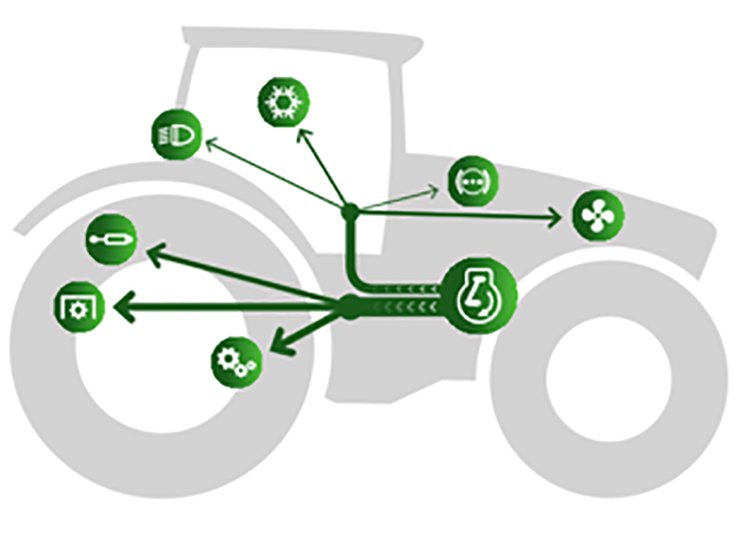

Settings and overview in the dashboard You can easily configure the main function groups in the main digital cockpit. To the left and right are the road travel information, on permanent display, and in the middle are four sections for different settings. In the non-display variant, you can easily control the main groups with the new pushdial on the right armrest: power lifts, hydraulics, engine and transmission, on-board computer with consumption readings, ventilation, lighting, front axle suspension, and valve assignment as well as service and diagnostics. As well as the familiar clover leaf operation, the new multifunction joystick includes two controls for proportional valve control as well as four freely assignable white keypads. This is where you can easily manage the usual transmission and driving functions with pushbuttons: including two engine speed programs, two cruise control settings and a new dial-controlled active cruise control setting. The lower control level includes the colored LED display for each setting. The driver immediately sees whether buttons have been re-allocated by the color concept. By default, these are the hydraulic valves. |

|

When we developed the new controls, we focused on intuitive operation as well as ergonomics. The multifunction joystick with improved handrest, for example, has been equipped with added functions, and the crossgate lever has been ergonomically optimized, making it easier to operate different attachments. The new joystick has a total of 18 buttons as well as two proportional buttons. Thirteen of these can be freely assigned.

|

As well as the well-known crossgate lever, the new 3L joystick with up to three operating levels and up to 27 functions is also available as an option. With the 3L joystick, you can control the front loaders Fendt Cargo and Fendt CargoProfi, including special functions. You can now use the third valve together with the 3L joystick and the Fendt front loaders to run three functions at the same time; use round baler forks to lift the front loader, retract the forks and close the clamp at the same time, for example. If your working day includes frequent changes of direction, the reverse drive button makes your work quicker and fatigue-free. As well as the well-known crossgate lever, the new 3L joystick with up to three operating levels and up to 27 functions is also available as an option. With the 3L joystick, you can control the front loaders Fendt Cargo and Fendt CargoProfi, including special functions. You can now use the third valve together with the 3L joystick and the Fendt front loaders to run three functions at the same time; use round baler forks to lift the front loader, retract the forks and close the clamp at the same time, for example. If your working day includes frequent changes of direction, the reverse drive button makes your work quicker and fatigue-free. |

|

|

|

|

|

300 Vario in 3 equipment versions Power, Profi and ProfiPlus

|

|

|

|

FendtONE – seamlessly connecting office and machine.

Consistent and intuitive operating philosophy For the first time, the new FendtONE platform merges your machines and your office into one control unit. FendtONE combines the familiar operation of the tractor with the terminal for planning or control tasks that classically would take place in the office. You can schedule field data and orders on your computer or smart device wherever you are and send them to your machine. The view from the driver's cab and online (from the office or on the move) is always the same. FendtONE helps you comply with legal documentation requirements and optimizes your entire work processes.

|

|

When new ideas and old values come together.

For the first time, you can use all the Fendt lane guidance and documentation options with the light and smart 300. The Contour Assistant adds the wayline types Contour Segments and Single Track to the existing types. The different segments are recorded by just a single lap around the field using the Contour Segments wayline type. Field boundaries can therefore be quickly and easily established. Use Single Track to record an almost endless track with an open contour. Parallel tracks are not automatically generated, and tramlines are stored as contour lines. |

|

With Fendt SectionControl for ISOBUS implements, you can apply seeds, fertilizers and pesticides without overlapping. This prevents double treatment, and distances are automatically maintained. |

|

Variable application with VariableRateControl (VRC) If you transfer data with Task Doc, you can apply variable quantities as required and make your resources last longer. Task Doc for documentation is part of the latest solution in precision farming. The individual requirements for seeds, fertilizers and pesticides are shown on application maps, for retrieval and automatic release on the job. |

|

Up to 7% more area coverage with front axle suspension The self-levelling front axle suspension with 80mm suspension guarantees the best traction and increases your area coverage by up to 7%. The ever powerful Vario drive also delivers the best driving safety even on hillsides or with front loader use. |

|

Three front power lift variants for precise adjustment and perfect traction The power lift with vibration damping is available with position control as standard, or as a comfort front power lift with position and load relief control. This all helps optimize your feed quality. You drive the mower in a “floating” fashion, with a support pressure defined in the terminal. It works at a constant height and follows the ground contour with precision. No need for conventional relief springs. The weight transferred from the implement to the front axle simultaneously increases traction and prevents drift on the hillside. Research studies confirm that this optimizes the feed quality, as the raw ash content in the feed decreases and the sward is not pierced. For winter work with a snow plough, the constant field pressure control provides uniform clearing results. |

|

The superior driving and working comfort of an HGV The intelligent combination of three systems guarantees maximum ride and operating comfort: lockable front axle suspension with anti-roll control, cab suspension (choose from mechanical or pneumatic) and active shock load stabilizing. This gives the front axle an even load, and the steering control is maintained. Together with the sensitive Fendt Reaction steering for safe straight-ahead work, the 300 offers truck-level driving and working comfort. |

|

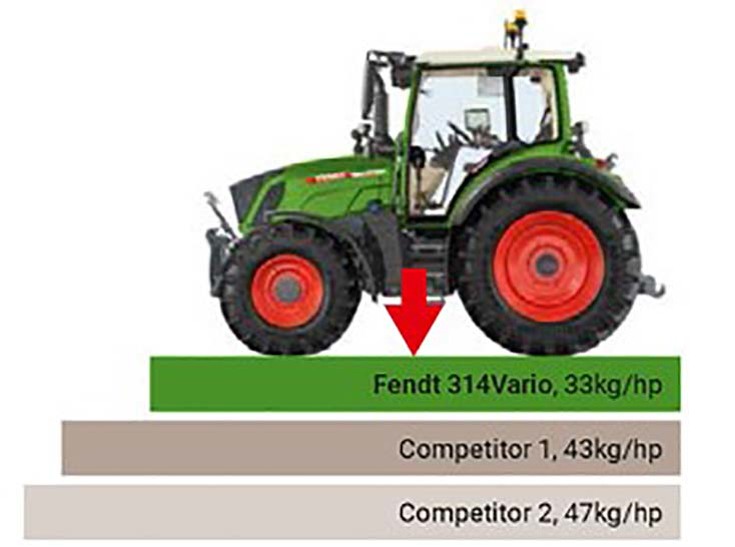

Outstanding value retention The superior value retention of a 300 is a solid building block for its overall economic efficiency because it costs less per hour/acre. Cutting-edge solutions like these often come to market years later. The benefit? A Fendt 300 is a real investment even after years of use. |