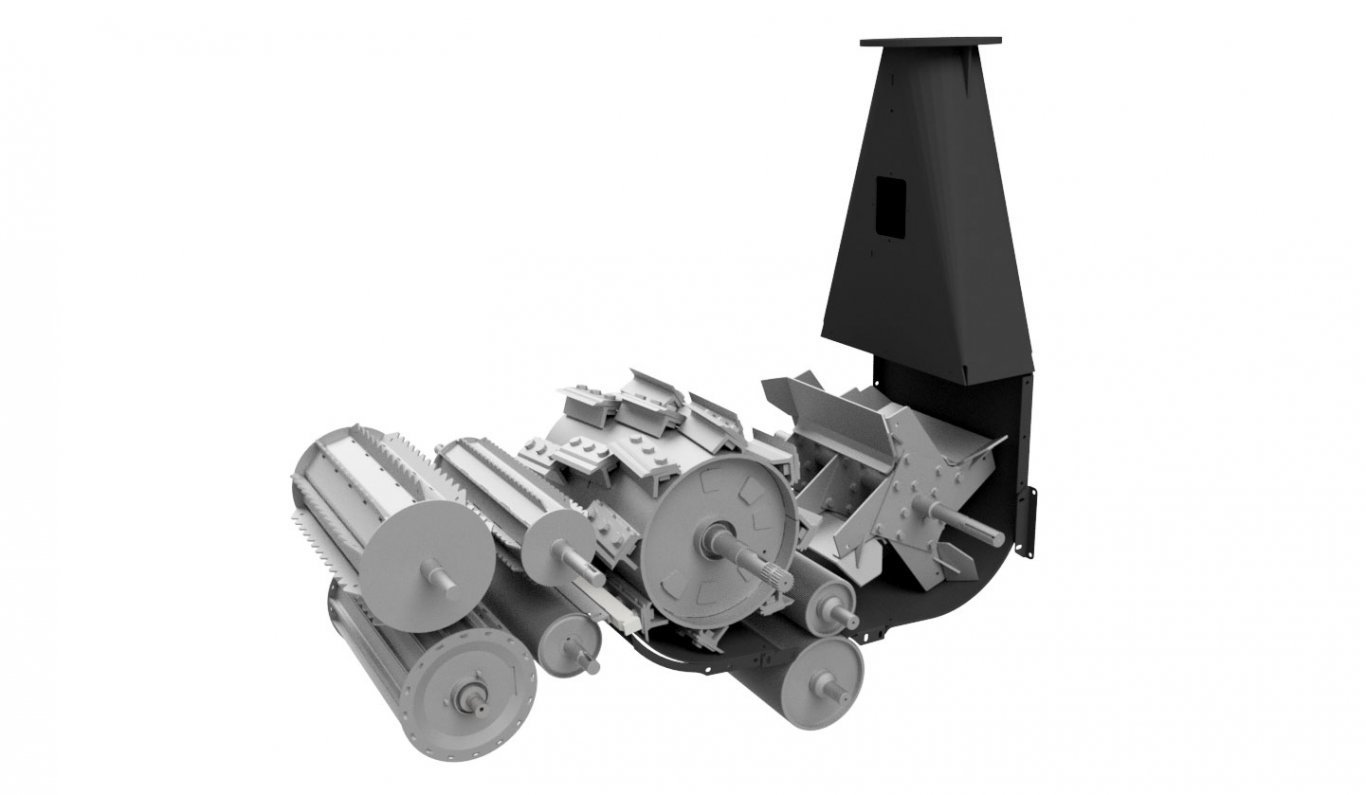

Exclusive straight-through design

Exclusive straight-through design

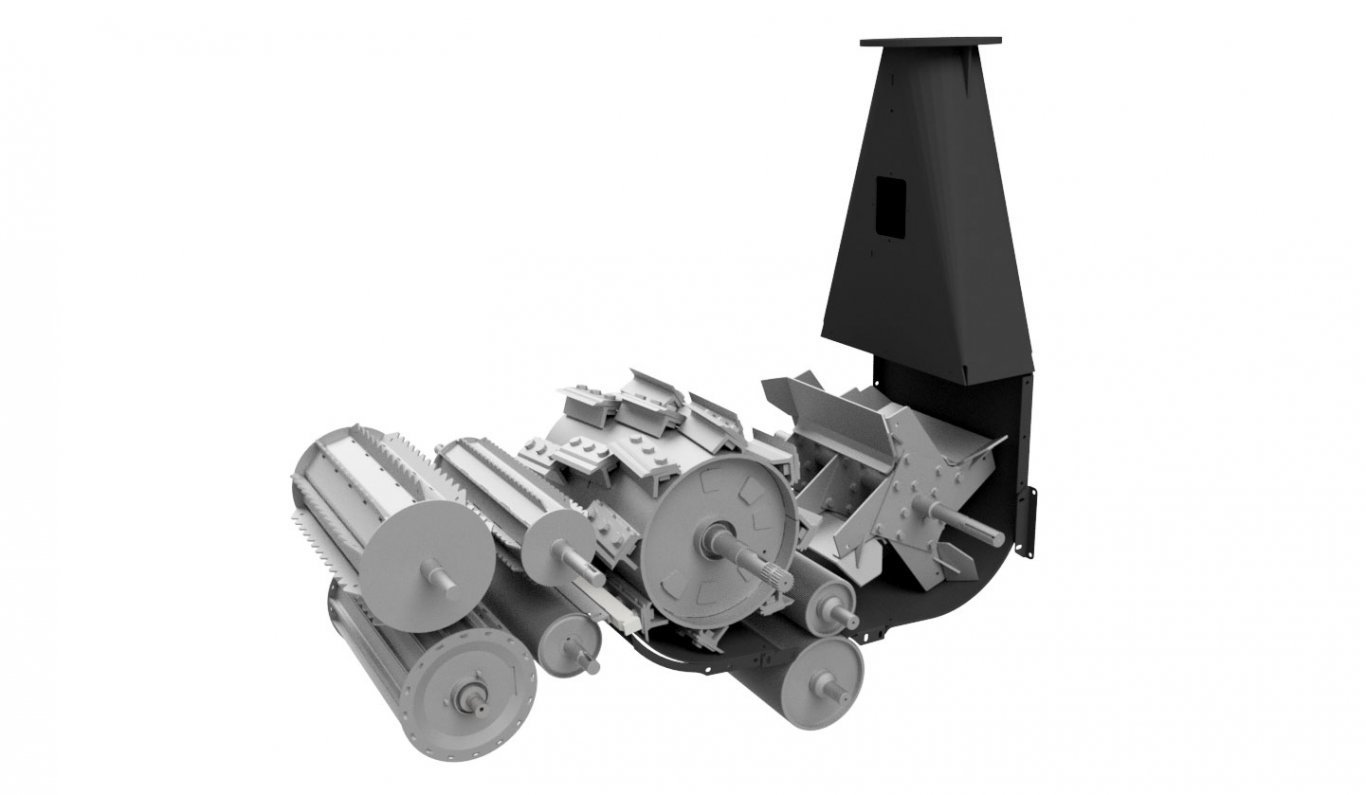

Without a transverse auger, the straight line flow of the Dion harvester makes it the most efficient on the market. The silage is accelerated in a progressive manner at every step, without abrupt change in direction & without energy loss. The same efficiency as a self-propelled harvester at a fraction of the cost. |

|

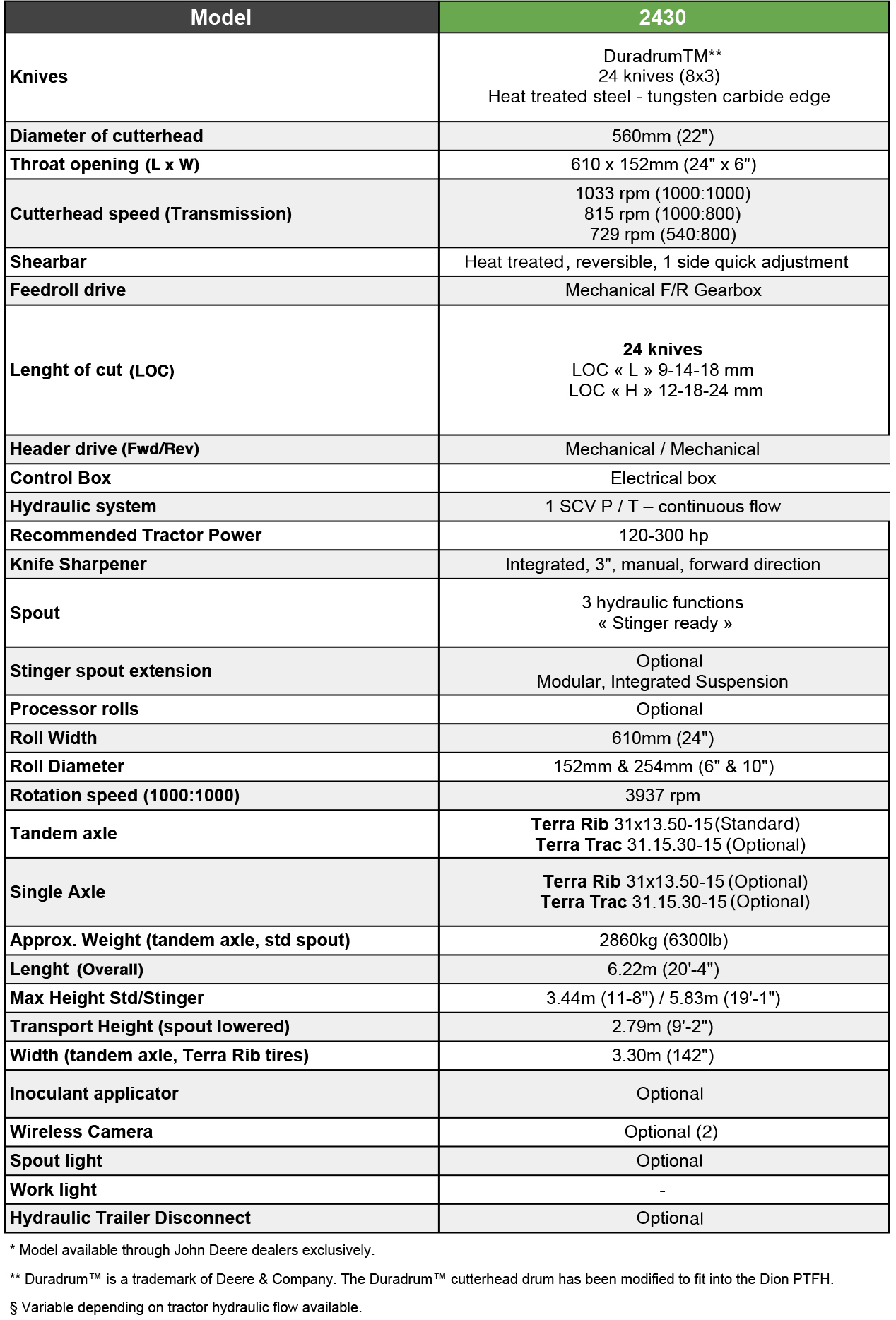

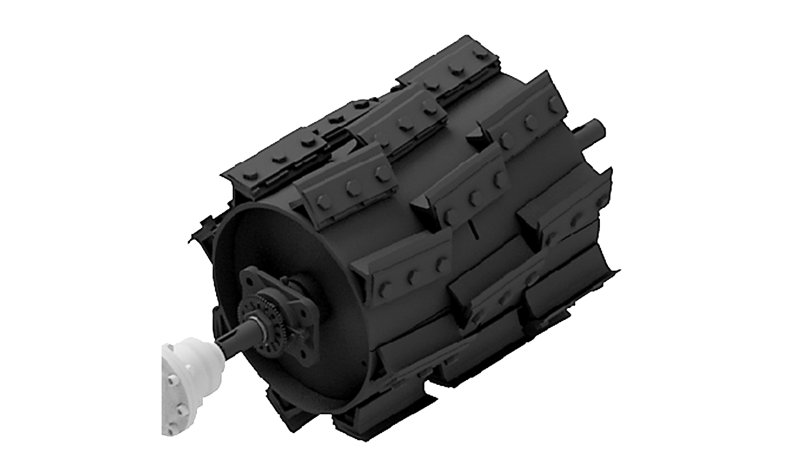

DuraDrum™ Cutterhead from John Deere

DuraDrum™ Cutterhead from John Deere

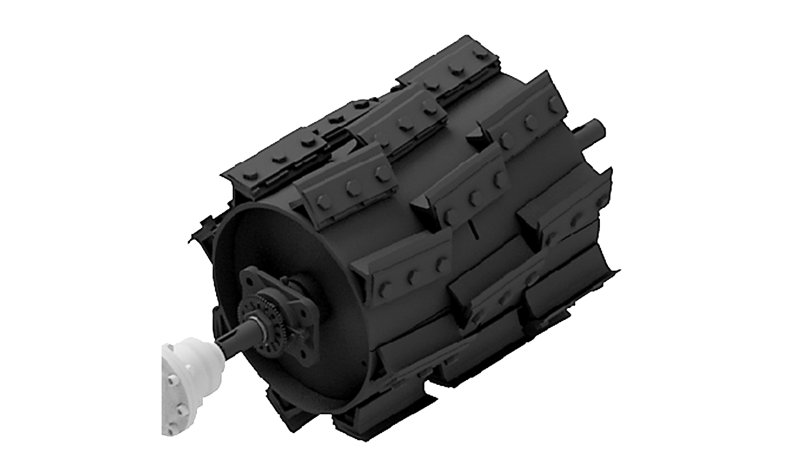

Exclusive to the Dion 2430, the cutterhead uses Duradrum™ segment knives similar to those found on the John Deere 7000 series self-propelled harvesters. Adapted to fit in the 2430, the cutterhead features 24 knives positioned on 3 rows of 8 knives. The knives, mounted at an angle, offer excellent quality of cut, high durability & easy replacement.

With two (2) choices of LOC range, maximize the capacity of your harvester no matter the conditions. Three (3) LOC sprockets are available from the factory. Cut up to 24mm (0.94in) in length with 8 knives (vs 6 knives for the competition), a configuration unique to Dion. |

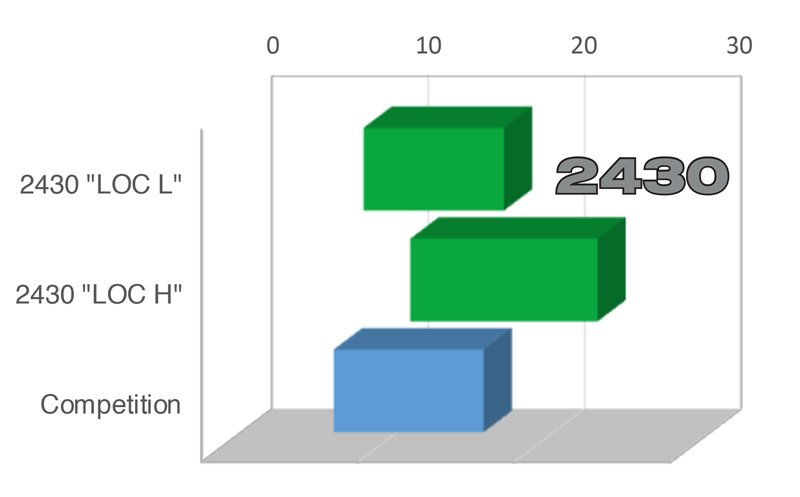

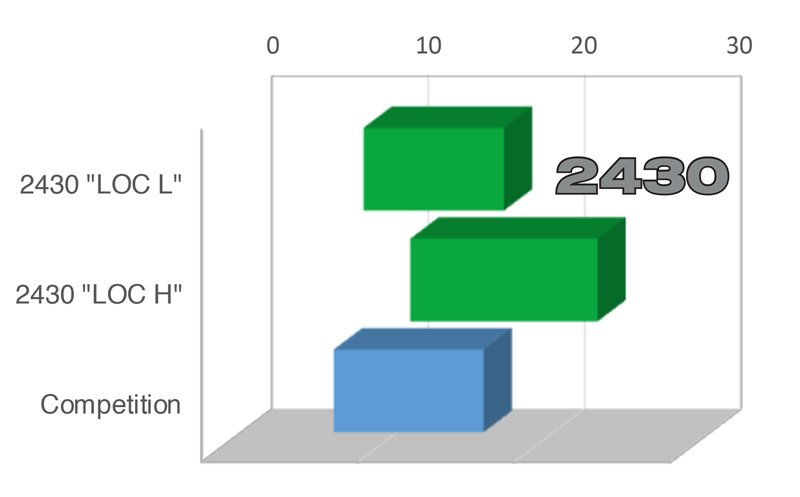

Range of Length of Cut – 24 knives (8x3) (mm)

Range of Length of Cut – 24 knives (8x3) (mm)

|

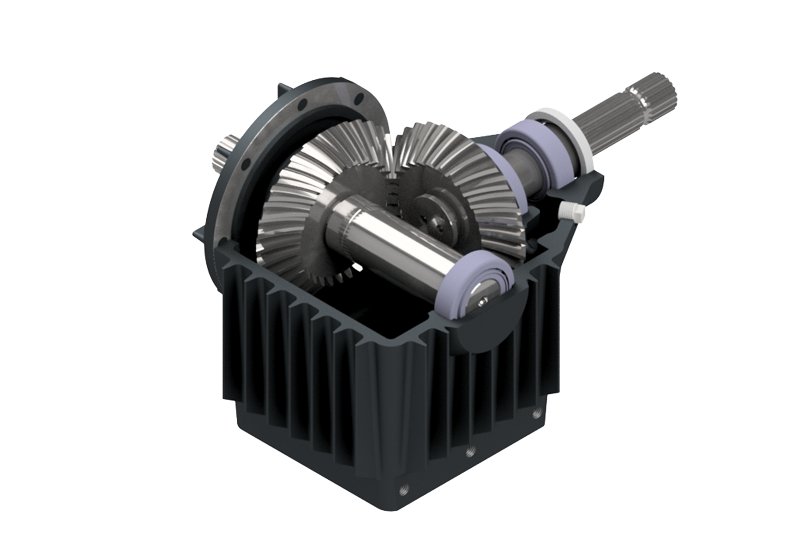

Unmatched Capacity

Unmatched Capacity

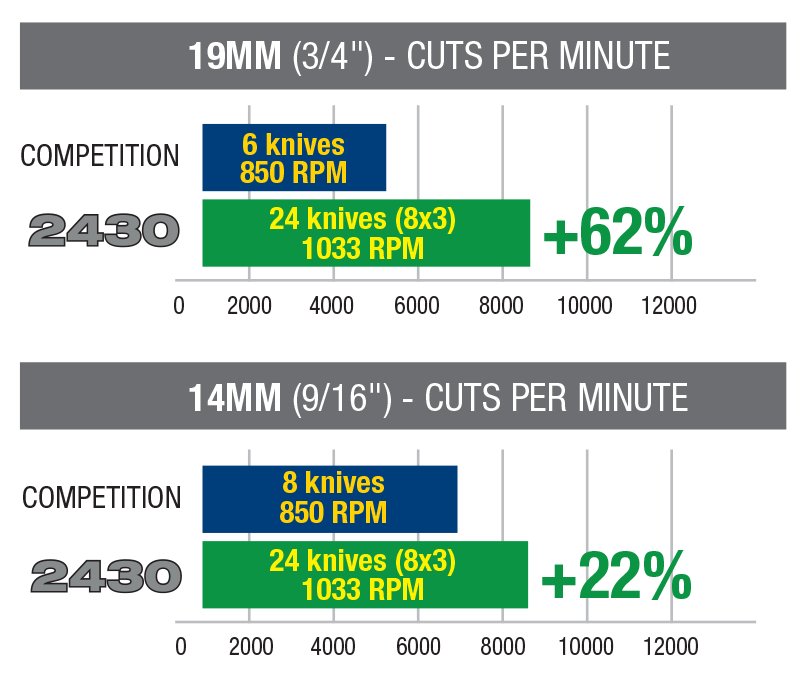

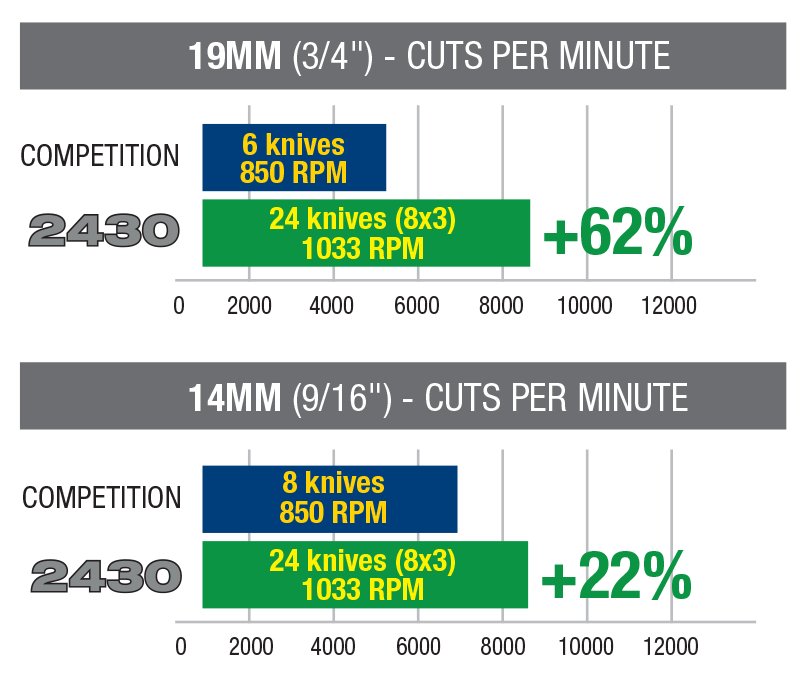

The secret behind the capacity of the Dion harvester resides in the rotation speed of the cutterhead. At 1033 rpm, it is 22% more cuts per minutes than the competition (and up to 62% more for certain lengths of cut*).

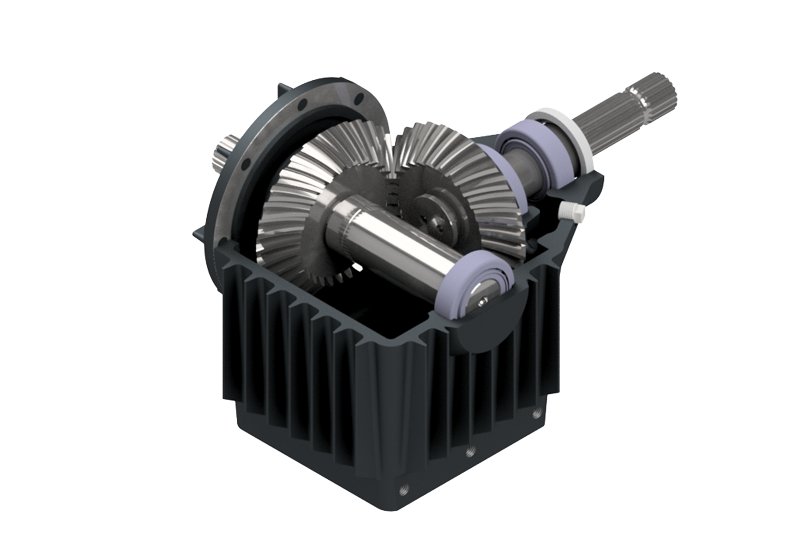

Exploit all the tractor’s power without constraint with throughputs exceeding 110 ton/h. The spiral bevel gears can handle 300hp (PTO power) without worry. Improved cooling and synthetic oil lubrication ensures great reliability.

For less powerful tractors (<160hp), a lower ratio gearbox configuration is available, providing a cutterhead speed of 825rpm.

Comparative example of 2 most common lengths of cut. Includes the maximum number of knives possible for the LOC and rotation speed of the cutterhead. |

|

Comparative example of 2 most common lengths of cut. Includes the maximum number of knives possible for the LOC and rotation speed of the cutterhead.

Comparative example of 2 most common lengths of cut. Includes the maximum number of knives possible for the LOC and rotation speed of the cutterhead. |

Simplified Sharpening & Adjustment

Simplified Sharpening & Adjustment

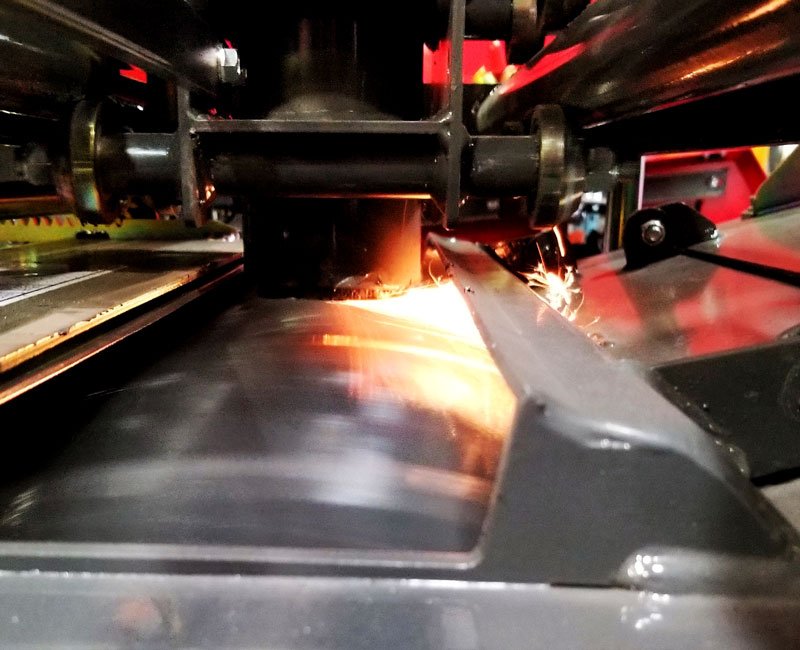

Nothing is more important for good harvester performance and silage quality than the sharpness of the knives and the shearbar adjustment. To make the task easier, the time to execute these tasks has been reduce by 50% compared to the previous models and nothing on the market can compare in terms of simplicity. The forward sharpening on Dion harvesters provides a razor sharp edge while drawing the sharpening heat away from the knife tip and without leaving a burr.

The simplified sequence reduces the sharpening and bar adjustment to two simple steps. Start the PTO, sharpen, and adjust! No driveshaft to disconnect, no repetitive travels between the tractor seat and the harvester. With a rack & pinion system, the shearbar is loosened by two lockers, standing on one side of the harvester. Sliding on integrated ramps, it moves parallel to the cutterhead by a single adjustment bolt. This simple method encourages the operator to maintain proper adjustments and knife sharpness. The reduction in wear, fuel consumption and resulting excellent silage quality will add up to gains in profitability. |

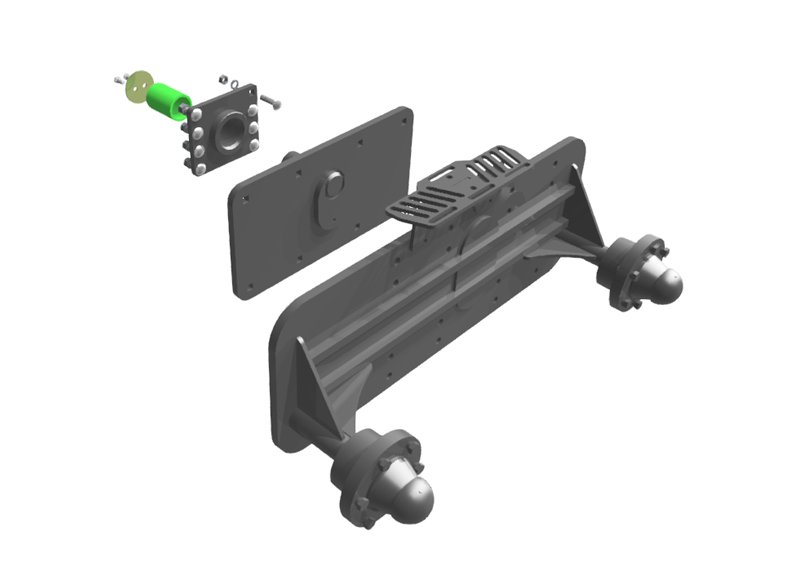

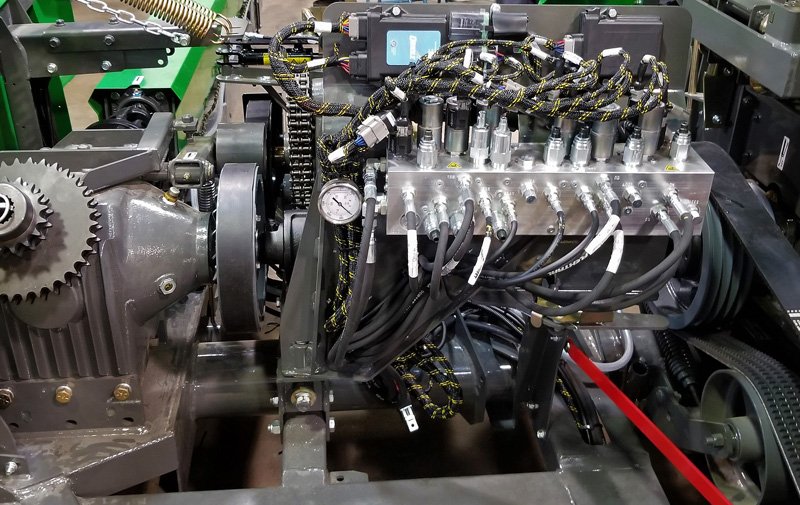

Electro-Hydraulic Functions

Electro-Hydraulic Functions

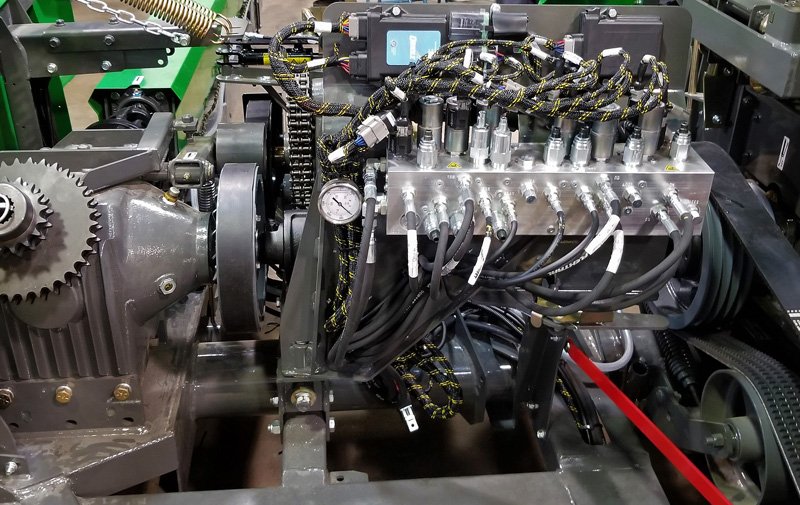

All harvester functions are regrouped in a distribution manifold with cartridge valves. This modular design is economical and easy to maintain. The hydraulic functions provide precision and power. For example, the F/R gearbox is shifted twice as fast as the previous generation with an electric actuator shifter. A single SCV is required for all functions with a low 3gpm continuous flow.

The control manifold operates the following functions:

//

3 spout functions (rotation, deflector, height)

//

F/R transmission shifting

//

Header height

//

Tongue position

//

Automatic trailer disconnect (option) |

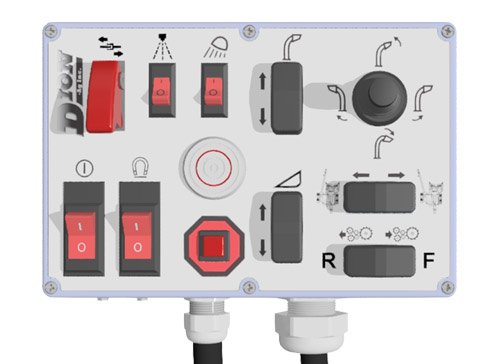

Redesigned Control Box

Redesigned Control Box

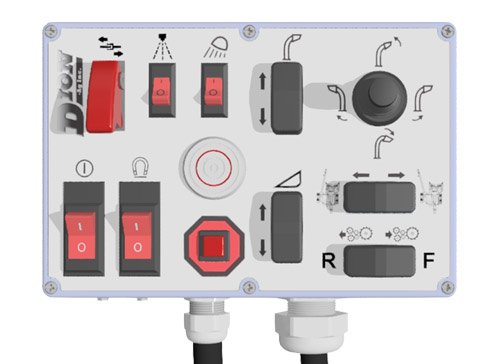

Ergonomic, compact and light, the DION 2430 control box integrates all the functions and options of the harvester. A joystick optimally positioned provides precise control of the spout. With the electro-hydraulic controls, the position of the tongue and header height are accessible in the same location. The addition of an optional spout light and inoculant/liquid applicator do not require any supplementary control box or modification, all is prewired and ready to operate. Same goes for the installation of a camera and its monitor, they are literally plug and play. You can set the control box in the perfect position with the included adjustable mount from RAM®. |

|

For even more flexibility, an auxiliary joystick duplicates the spout controls in any location in the tractor cab. Offered optionally, it connects directly to pre-wired control box.

For even more flexibility, an auxiliary joystick duplicates the spout controls in any location in the tractor cab. Offered optionally, it connects directly to pre-wired control box. |

|

The DION 2430 features high quality cabling with all sealed Deutsch connectors. The low amperage, required by the system, allows you to connect the box directly to the in-cab 12V power outlets.

The DION 2430 features high quality cabling with all sealed Deutsch connectors. The low amperage, required by the system, allows you to connect the box directly to the in-cab 12V power outlets. |

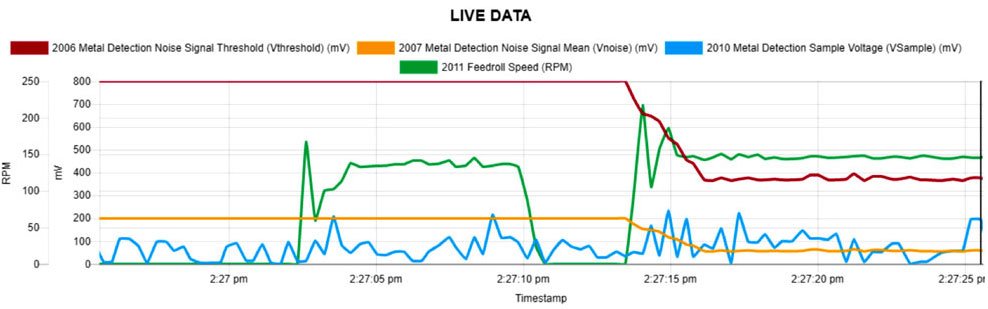

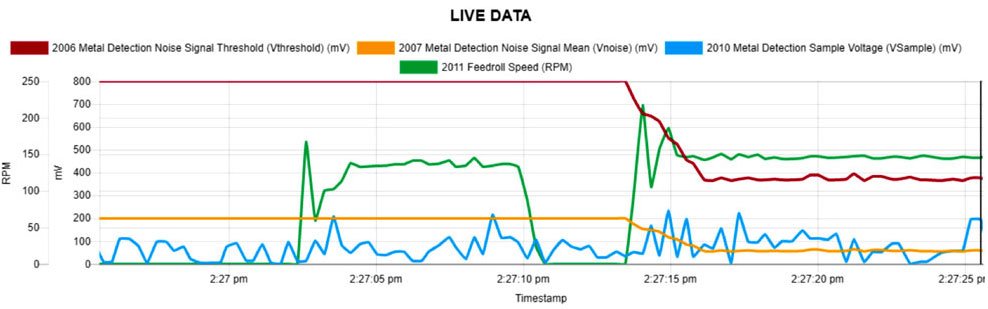

The FerroDtec Precision

The FerroDtec Precision

The new FerroDtec metal detector from Dion combines precision and reliability. Programmed on powerful controllers, it offers an exceptional reaction time. The new algorithm allows for precise and reliable detections while reducing the risk of time consuming false detections. The detection threshold is automatically calibrated to the condition of the crop and the wear or damage of the detector feedroll. Three levels of sensitivity, selectable manually, allow you to adapt to any requirement. |

|

With speed sensors installed on the cutterhead and the feedrolls, an anti-plugging function is standard. It ensures the feedrolls are stopped immediately in case of an overload of the cutterhead (cutterhead drive shearbolt breakage). The unit’s detailed alarms allow you to quickly determine the causes of emergency stops and diagnose potential problems.

With speed sensors installed on the cutterhead and the feedrolls, an anti-plugging function is standard. It ensures the feedrolls are stopped immediately in case of an overload of the cutterhead (cutterhead drive shearbolt breakage). The unit’s detailed alarms allow you to quickly determine the causes of emergency stops and diagnose potential problems. |

|

We believe the benefits of technology should not be a burden to reliability. In case of a sensor failure, the electronic functions can be deactivated to ensure you can complete your day of harvest in time without compromising the silage quality. Your dealer is equipped with a complete service and diagnostic software that allows the technician to analyse the performance of the electronic system. Through the Wi-Fi connection on a laptop computer, the live system data can be displayed, even from the cab while harvesting in the field! A faster and more precise diagnostic results in less repair costs. The harvester control software updates are done quickly and easily and allow you to benefit from eventual system improvements.

We believe the benefits of technology should not be a burden to reliability. In case of a sensor failure, the electronic functions can be deactivated to ensure you can complete your day of harvest in time without compromising the silage quality. Your dealer is equipped with a complete service and diagnostic software that allows the technician to analyse the performance of the electronic system. Through the Wi-Fi connection on a laptop computer, the live system data can be displayed, even from the cab while harvesting in the field! A faster and more precise diagnostic results in less repair costs. The harvester control software updates are done quickly and easily and allow you to benefit from eventual system improvements. |

The Unique Stinger Spout

The Unique Stinger Spout

With exceptional dimensions, the 2nd generation Stinger spout loads on any side, even the tallest trailers. The accelerator/blower power of the DION allows side-loading to considerably reduce trailer switching time for even more productivity.

// Max height : 5.8m (19ft)

// Rotation : 330 deg

Mounted on a solid base, the DION 2430 is “Stinger ready” as a standard feature. A double deflector, also standard, ensures a precise filling in pull-behind trailers as well as for side loading. Even in short configuration, you benefit from an ultra-durable 1/4in thick Hardox wear plate. Accessible directly from the top, it can be replaced in a few minutes. |

|

Reach the next level with the Stinger extension option which can be “dealer or field installed” very quickly. No additional brace or support is required. Also, the transition between the short and long configuration is done in a few minutes: ideal for contractors. Optional for the standard spout configuration, a wireless camera and LED spout light are standard with the Stinger extension. They let you harvest on both sides with ease.

Reach the next level with the Stinger extension option which can be “dealer or field installed” very quickly. No additional brace or support is required. Also, the transition between the short and long configuration is done in a few minutes: ideal for contractors. Optional for the standard spout configuration, a wireless camera and LED spout light are standard with the Stinger extension. They let you harvest on both sides with ease. |

|

|

The redesigned dual accumulator suspension provides a smooth ride in Stinger configuration. For road transport, the spout is lowered at a height below 3m (10ft). The suspension absorbs the impacts or road imperfections no matter the speed. When set in transport position, the rotation is automatically locked for safe travels between fields.

The redesigned dual accumulator suspension provides a smooth ride in Stinger configuration. For road transport, the spout is lowered at a height below 3m (10ft). The suspension absorbs the impacts or road imperfections no matter the speed. When set in transport position, the rotation is automatically locked for safe travels between fields. |

Shear Processing with τSτ

Shear Processing with τSτ

A proven concept, exclusive to Dion, the optional processor rolls of the DION 2430 uses a shearing effect to process the particles and pulverise the kernels in corn silage. With a differential speed ratio of 67%, the highest on the market, the particles are torn lengthwise and the grain is processed with low crushing pressure. This reduces compression forces and improves KP bearing life all while reducing power requirements.

The lower 10” roll is paired with the smaller 6” top roll, both turning at close to 4000rpm. They are positioned directly in the crop flow trajectory to eliminate direction changes and lower energy consumption. Obtain the desired level of silage processing at any time by simply adjusting the clearance of the processor rolls, in a few seconds, with a single wrench. |

|

The conversion time between corn silage configuration and haylage has been reduce by approximately 30% compared with the previous models. The top roll is completely removed by sliding it out towards the inside of the harvester where it can be stored onboard to reduce handling. No major parts need to be removed or displaced. It is done with a single wrench, with less effort and all adjustments are preserved for a quick reinstallation.

The conversion time between corn silage configuration and haylage has been reduce by approximately 30% compared with the previous models. The top roll is completely removed by sliding it out towards the inside of the harvester where it can be stored onboard to reduce handling. No major parts need to be removed or displaced. It is done with a single wrench, with less effort and all adjustments are preserved for a quick reinstallation. |

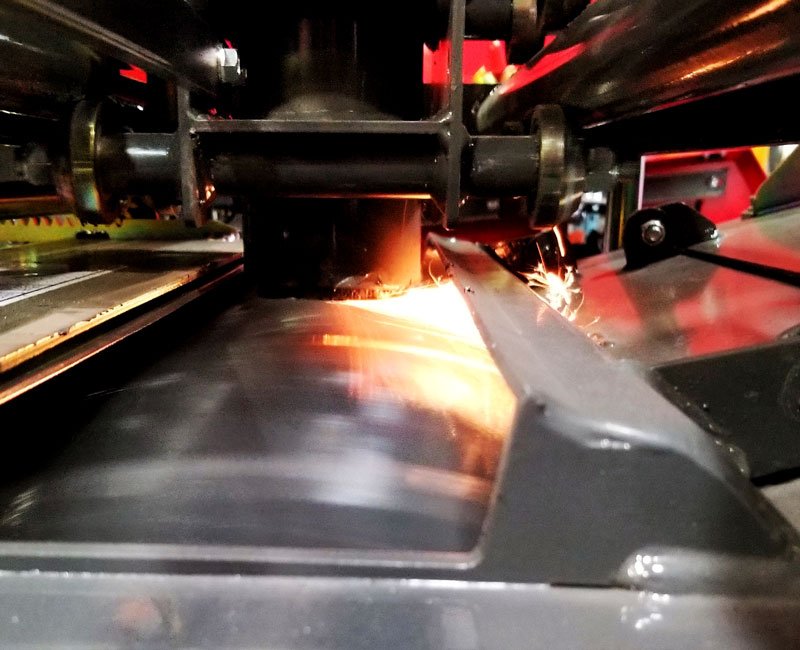

Manufacturing Quality

Manufacturing Quality

The desire to provide a durable and modern product was part of the design process of this new generation of harvesters. The rated power of the driveline has been increased. Premium quality, banded belts, have been selected for highest durability and power transmission capacity. |

Practical and Ergonomic

Practical and Ergonomic

Harvest in style with the new color scheme and completely redesign guards. A large main guard opens with ease to access the drive components. The access is direct to the length of cut chain binder for easy adjustment. The hydraulic module pivots to give access to the service points. "Butterfly” guards protect the core of the harvester and the sharpening system from debris accumulation.

The completely new tongue combines rigidity and accessibility. Cable and hose routing have been improved. Finally, remain visible at any moment with the LED transport lights. |

|